I started building an adjustable box, or finger, joint jig last night. I've wanted to make one of these for a long time but just never got to it. My work hours still are pretty limited in the evenings as to when noise is acceptable in the 'hood', but eventually I can still get things done. So far I've managed to cut the basic parts and fit them. The bulk of this jig will be made using maple. The sacrificial fence sections... and I cut a bunch of them for future use... are simply 1/4-inch hardboard.

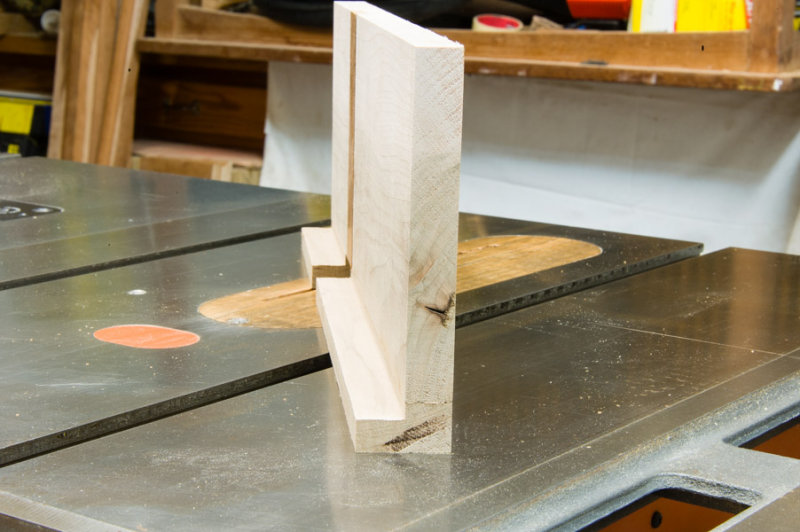

The right side of the fence and shelf shown above will be glued together as one piece. The left side will form the adjustment assembly and slide freely to regulate the finger width.

The back right side of the jig here shows the pieces that will form the adjustment assembly. After I photographed this I realized the vertical pieces were reversed. The shorter piece is the same length as the shelf section, and the two will be glued together to form one unit. The longer piece will then be sandwiched in the center behind the fence and serve to adjust the finger width. The next step will be to cut slots in these pieces to allow them to move back and forth. I'm not sure yet if I'll try and do this with the router or simply drill and file them. But I've laid everything out for the next night of work.

I also built a little right angle jig (not shown yet) to aid in drilling into the end grain of the adjustment pieces. I'll probably post that shot "in use" along with why I need to drill into end grain.

I managed to get a nice match between the bottom shelf section and the width of the fence. But it took a couple passed thru the thickness planer to get it. :) I've had a nice pair of Freud box joint blades for some time... but never used them because I didn't have a jig setup. But the plans and hardware to build this setup came a week or so ago and that put the heat on, so to speak. And speaking of heat... I don't work with maple much. And it has a strong tendency to burn if you don't get the feed rate thru the saw just right. It's pretty obvious that I haven't got that worked out yet. :)

More to follow as I continue this fun little build. I was sooo tempted at one point to buy the Incra rig. But this should be just as nice and save me a bundle of coin in the process.

The right side of the fence and shelf shown above will be glued together as one piece. The left side will form the adjustment assembly and slide freely to regulate the finger width.

The back right side of the jig here shows the pieces that will form the adjustment assembly. After I photographed this I realized the vertical pieces were reversed. The shorter piece is the same length as the shelf section, and the two will be glued together to form one unit. The longer piece will then be sandwiched in the center behind the fence and serve to adjust the finger width. The next step will be to cut slots in these pieces to allow them to move back and forth. I'm not sure yet if I'll try and do this with the router or simply drill and file them. But I've laid everything out for the next night of work.

I also built a little right angle jig (not shown yet) to aid in drilling into the end grain of the adjustment pieces. I'll probably post that shot "in use" along with why I need to drill into end grain.

I managed to get a nice match between the bottom shelf section and the width of the fence. But it took a couple passed thru the thickness planer to get it. :) I've had a nice pair of Freud box joint blades for some time... but never used them because I didn't have a jig setup. But the plans and hardware to build this setup came a week or so ago and that put the heat on, so to speak. And speaking of heat... I don't work with maple much. And it has a strong tendency to burn if you don't get the feed rate thru the saw just right. It's pretty obvious that I haven't got that worked out yet. :)

More to follow as I continue this fun little build. I was sooo tempted at one point to buy the Incra rig. But this should be just as nice and save me a bundle of coin in the process.

No comments:

Post a Comment